PRODUCTS

FOR SODIUM

HYPOCHLORITE

Chemline offers valves that effectively manage sodium hypochlorite chemicals while delivering efficiency, safety and reliability. Ideal for municipal water and wastewater applications, these valves can be combined with ChemFlare™ PFA fittings, tubing and end connectors or our ECTFE (Halar™) rigid piping system to provide leak-free service with a 25-year life expectancy. Single wall and dual containment configurations are available and are quick and easy to install. No curing time is required and the system can be tested immediately. With our systems, municipalities can look forward to not just meeting but exceeding regulatory standards, ensuring the safety of personnel, communities, and the environment at large. In the evolving landscape of chemical management, ChemFlare™ stands out as a beacon of innovation, reliability and excellence.

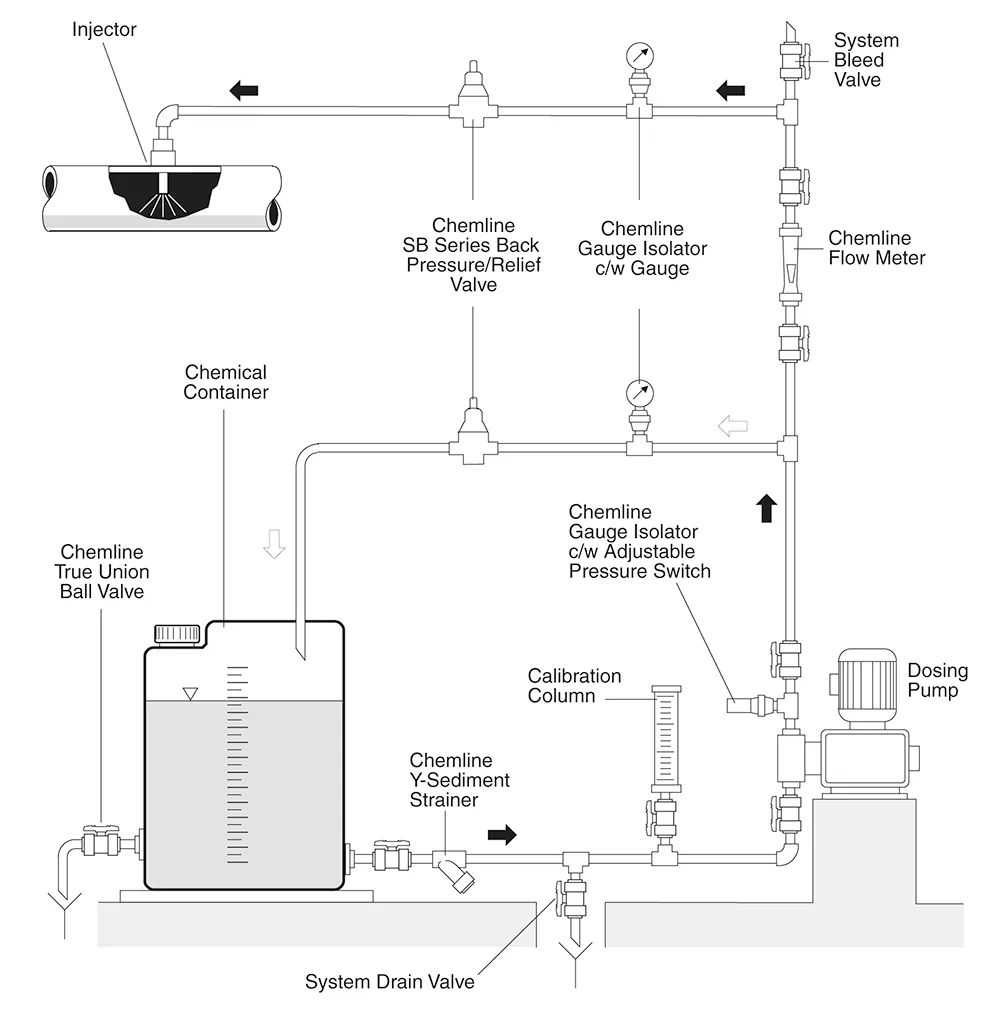

What does a typical dosing system look like?

Why is sodium hypochlorite so difficult to handle in a PVC threaded or cemented socket system?

Why are vented ball valves required in a sodium hypochlorite dosing system?

What are connection options for valves in a sodium hypochlorite system?

What is a single wall system?

What is a dual containment system?

Download our ChemFlare™ for Sodium Hypochlorite Brochure

Download our ChemFlare™ for Municipal Applications Brochure

Download our Type 24 Ball Valves with Vented Ball for Sodium Hypochlorite Data Sheet

Download our Product Line Brochure

Download our Valve Specification Guide

Download our Chemical Resistance Guide

Products For Sodium Hypochlorite

Valves for Sodium Hypochlorite Applications

| Materials | Sizes | Set Pressure Range | Major Features | Model |

|---|---|---|---|---|

| PVC | 1/2” to 2” | Not Applicable | NSF Approved | Type 25 with vented ball |

| PVC | 1/2” to 4” | Not Applicable | NSF Approved | Type 24 with vented ball |

| PVC, PP, PVDF | 3/8” to 1” | 3 to 150 psi | Best for sodium hypochlorite service | SB10/11 Series Hypo |

| PVC, PP, PVDF | 3/8” to 1” | 5 to 150 psi | Built-in check function | SB12 Series Back Pressure / Relief |

| PVC, PP, PVDF | 3/8” to 1” | 7.5 to 150 psi | Recommended for dosing | SB18 Series Back Pressure / Relief |

Products For Chemical Feed Applications

What does a typical dosing system look like?

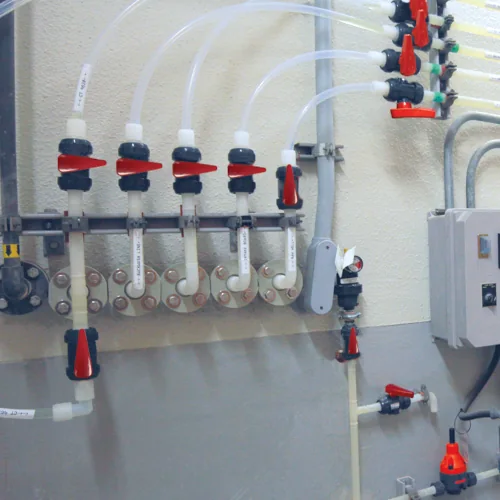

A typical dosing system for sodium hypochlorite is designed to accurately and safely introduce the chemical into a water treatment or disinfection process. The dosing system typically consists of several components to ensure precise control of the sodium hypochlorite dosage. We offer ball and back pressure/relief valves, gauge isolators, flow meters, calibration columns, y-sediment strainers and corporation stops, all required for dosing systems.

Why is sodium hypochlorite so difficult to handle in a PVC threaded or cemented socket system?

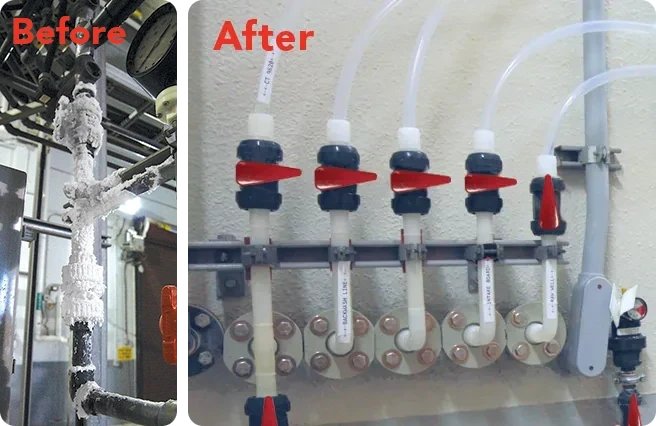

Due to the corrosive properties of sodium hypochlorite, typical PVC cemented socket or threaded connections are prone to leaks. When sodium hypochlorite attacks the valve connection joints, leaks result. When the chemical leaks it comes into contact with air where it oxidizes and forms crystals that accumulate at the joints causing a safety hazard.

Why are vented ball valves required in a sodium hypochlorite dosing system?

Sodium hypochlorite is a chemical compound commonly used as a disinfectant. When stored or transported, sodium hypochlorite can release chlorine gas, especially when it comes into contact with acidic or reactive substances. Chlorine gas is toxic and can pose health hazards.

A vented ball is required for ball valves in a sodium hypochlorite system to allow the release of any gas that may build up inside the valve. This venting is crucial for safety reasons. If gas pressure were to build up within a sealed system, it could lead to the risk of the container bursting or leaking, causing exposure to chlorine gas. The vented ball is designed to release pressure and prevent the accumulation of potentially hazardous gases.

In summary, the use of a vented ball for sodium hypochlorite is a safety measure to mitigate the risk of pressure buildup and the release of toxic chlorine gas. It helps to ensure safe handling, storage, and transportation of sodium hypochlorite.

What are connection options for valves in a sodium hypochlorite system?

We offer 2 connection options for our valves in sodium hypochlorite applications. Both offer long term, leak-free service and are superior to typical cemented or threaded versions available in typical PVC systems. Our ChemFlare™ flexible tubing system is a flared mechanical solution and if offered ½” to 1”. Our ECTFE Rigid piping system features butt fusion welded connections and fittings offered ½” to 4”. Both systems are offered in single wall or dual containment systems for maximum safety.

What is a single wall system?

For a ChemFlare™ flexible PFA system:

- Chemline’s ChemFlare™ system is the long term leak-free alternative to standard PVC solvent welded piping on sodium hypochlorite chemical feed systems. Valves, controls and pumps with ChemFlareTM ends connect to ChemFlare™ fittings and PFA tubing.

- 25 years life expectancy for leak-free and maintenancefree service on sodium hypochlorite

- Systems are easy to install

- Mechanical connections

- No welding or curing waiting time, may be pressure tested immediately

- True Union valve sizes: 1/2”, 3/4” & 1”

- Tubing sizes: 1/4”, 3/8”, 1/2”, 3/4” & 1”

For a rigid ECTFE piping system:

- Chemline’s ECTFE piping system is the long-term leak-free alternative to standard PVC solvent welded piping on sodium hypochlorite chemical feed systems. Valves, controls and pumps with ECTFE butt-fusion ends connect to Chemline’s ECTFE butt-fusion fittings and pipe.

- 25 years life expectancy for leak-free and maintenance-free service on sodium hypochlorite

- Systems are easy to install

- Butt-fused connections

- Short welding waiting time, may be pressure tested as soon as the joints are cool to the touch

- True Union valve sizes: 1/2”, 3/4”, 1”, 1-1/4”, 1-1/2”, 2”, 2-1/2”, 3” & 4”

- Piping sizes: 1/2”, 3/4”, 1”, 1-1/4”, 1-1/2”, 2”, 2-1/2”, 3” & 4”

Do you have leaking chemicals? Consider a retrofit. Call Chemline to arrange a site visit.

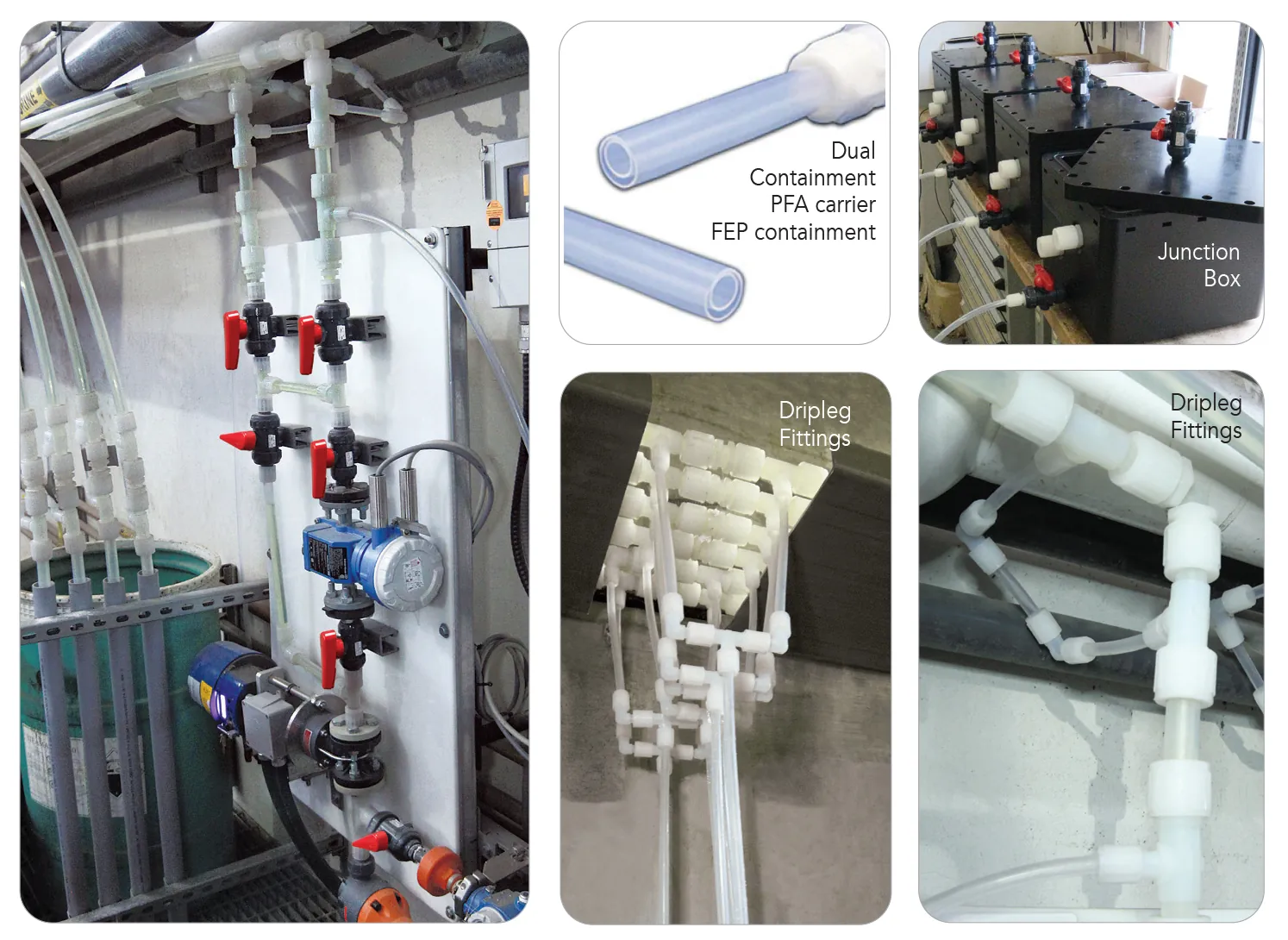

What is a dual containment system?

For a ChemFlare™ flexible PFA system:

For maximum safety level of chemical containment

Tubing

- The carrier (inner) tube of PFA is the primary chemical line. The containment (outer) tube of FEP is translucent, permitting good visibility of the carrier tube.

Specialty Fittings

- Dripleg Fittings

- Dual containment tubing assemblies

- Dual containment splitter boxes

- Junction Boxes

Tubing Sizes O.D.

PFA Primary/FEP Containment

1/4”/1/2”

3/8”/3/4”

1/2”/3/4”

3/4”/1”

For a rigid ECTFE piping system:

For maximum safety level of chemical containment

Piping

The carrier (inner) pipe of ECTFE is the primary chemical line. The containment (outer) pipe of black HDPE, permitting use in outdoor and buried applications

Specialty Fittings

- Leak detection access Tees

- Low point leak detection stations

- Termination fittings for use with single-wall-pipe

- Dual containment valve boxes