Contact Butt Fusion Welders – W Series

W-Series Butt Fusion Welders

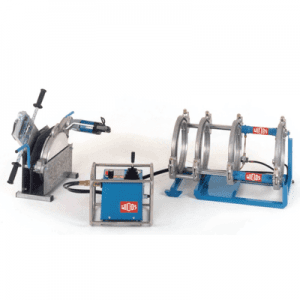

W-Series Shop/Field Welders are field hydraulic units with double clamping but the outer fixed side clamp and base can be easily detached, making this unit capable of welding in tight spaces. The electro-hydraulic control unit operates the clamps and controls the welding forces. The electronically controlled heating element has a digital display, control lamps, an on/off switch and a connection cable with shockproof plug. Both the heater and planer sit in a heat-protected storage box when not in use, and plug directly into the electro-hydraulic control box for convenience, avoiding multiple extension cords.

The W Series is a hydraulic welding machine for heating element butt welding PE, PP, PVDF and ECTFE pipes and fittings for use on building sites and in trenches. The pipe clamps accept reducers for different pipe sizes.

The W Series hydrualic welder is a double clamping machine with two pipe clamps fastened to the steel pipe frame on either side of the weld area, the fixed side and the movable side guided by hydraulic cylinders. The outer fixed side clamp and base can be easily detached in order to weld in badly accessible places, such as piping repair work in trenches or branches of T-pieces. The electro-hydraulic unit moves the right-hand clamps, controls the welding forces and has a pressure backup for supporting the welding force during the cooling down, using two quick-disconnect hoses attached to the movable side of the welder. It also has a pressure gauge for the exact indication of the pressure. The planer is operated by suspending in the welder guide shafts, has housed chain drive, a security micro switch with lock and an automatic external chip removal. The electronically controlled heating element is also operated by suspending in the guide shafts, has an anti-stick coating, digital display, control lamps, and on/off switch and a connection cable with shock-proof plug. The built-in separating device prevents the heating element from sticking to the pipe after the heating process. Both the heater and the planer plug into the electro-hydraulic control box for convenience, avoiding multiple extension cords.

A heat-protected box is provided for the safe storage of the planer and the heating element. A metal box serves for the transport and the protected storage of the complete W-Series welding kit.

Optional split heating elements for dual-containment staggered welding are available.

-

Size:1-1/2" to 24" (50mm to 610mm)

-

Fusion Type:Contact Butt Fusion

-

Materials:PE, PP, PVDF, ECTFE

-

Control:Hydraulic

-

Models:W4400: 1 1/2 - 6" (50 - 160mm)

W4600: 2 1/2" - 10" (75 - 250mm)

W4900: 3" - 10" (90-315mm)

W5100: 8? - 18? (200-450mm)

W5500: 8" - 20" (200-500mm)

W6100: 12" - 24" (315 - 630mm)

1-1/2" to 24" (50mm to 610mm)

Contact Butt Fusion

PE, PP, PVDF, ECTFE

Hydraulic

W4400: 1 1/2 - 6" (50 - 160mm)

W4600: 2 1/2" - 10" (75 - 250mm)

W4900: 3" - 10" (90-315mm)

W5100: 8? - 18? (200-450mm)

W5500: 8" - 20" (200-500mm)

W6100: 12" - 24" (315 - 630mm)

Features & Benefits

- Compact design ideal for inside trenches

Breaks down to 3 clamps for tight spaces - Rugged frame for industrial applications

- Adjustable speed to control change-over time

- Adjustable heating element temperatures

- Powerful planer with safety shut-off switch

- Can do vertical or horizontal welds

Technical Documents

Commonly used in these markets

Process Industrial

Chemical, Storage & Transport

High Purity Water

Utility Water

Valve Specification Guide

Engineering specifications are crucial as they provide precision, clarity, quality assurance and compliance in your projects. Download to save you time and assure accuracy in your specifications.

Chemical Resistance Guide

Corrosion resistance is an important factor in selecting the right material of construction for valves, pipe, tubing, fittings and more. Designed to easily navigate, this guide can be downloaded for easy reference.

Materials of Construction

Understanding materials of construction is essential to the accurate selection of valves, pipe, tubing, fittings and more. Designed to easily navigate, this guide can be downloaded for easy reference.