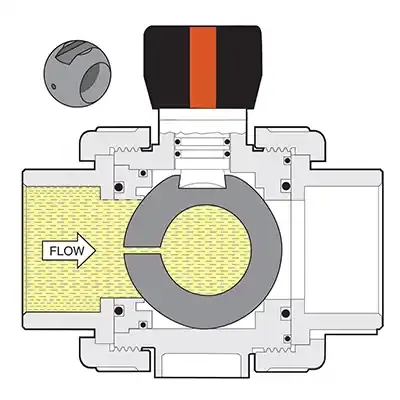

True Union ball valves for Sodium Hypochlorite applications – Type 25 with vented ball

The Chemline Type 25 True Union ball valve is a great choice for sodium hypochlorite service. We offer both ChemFlare™ end connectors and ECTFE (Halar®) butt fusion end connections for rigid pipe applications.

The Type 25 ball valve with vented ball connects to the ChemFlare™ flexible PFA tubing system and the ECTFE (Halar®) rigid piping system. Both are long term leak-free systems for sodium hypochlorite applications.

-

Size:1/2" to 2"

-

Ends:1/2" to 1" : Chemflare™1/2" to 2" : ECTFE (Halar®)

-

Seats:PTFE

-

Seals:FKM (Viton®)

-

Pipe Sizes:1/2" to 2"

-

Tube Sizes:1/4" to 1"

1/2" to 2"

1/2" to 1" : Chemflare™1/2" to 2" : ECTFE (Halar®)

PTFE

FKM (Viton®)

1/2" to 2"

1/4" to 1"

Features & Benefits

- Full Valve Working Pressure of 230 psi

- Full Port

High capacity and low pressure drops - Superior Stem/Handle Design for Durability

More secure stem/handle engagement

On high cycling applications Type 25’s have outlasted Type 21 valves with traditional Double D stem design - Safety Shear Stem Design

Stem has double o-rings. Designed to hold full pressure even if stem breaks due to excessive torque. - Ergonomic Handle

Easy to operate

With manual thumb lock

Can indicate flow direction - Panel Mountable

Threaded inserts in valve base allow valve to be securely anchored to panel or support - Vented Ball

Recommended for all sodium hypochlorite services

With ChemFlare™ system

- Weldless Design

Eliminates all fusion welds and cemented joins

Threaded connection between flared end and tube nut is not wetted - Easy Installation

Flaring the tube ends is easy

Assembly is by hand - Low Down Time

No welding or curing waiting time. The system may be pressure tested immediately. - Minimum Dead Volume

The flared tubing connection has minimum dead volume desirable on sodium hypochlorite and ultrapure applications.

With ECTFE (Halar®) system

- Butt Fusion Design

O-ring seal at valve face, with direct fusion to Chemline piping

Guaranteed leak-free design

No wetted threads or cemented joints - Low Down Time

Low wait time, the system may be pressure tested in minutes, not hours

Technical Documents

Commonly used in these markets

Environmental

Valve Specification Guide

Engineering specifications are crucial as they provide precision, clarity, quality assurance and compliance in your projects. Download to save you time and assure accuracy in your specifications.

Chemical Resistance Guide

Corrosion resistance is an important factor in selecting the right material of construction for valves, pipe, tubing, fittings and more. Designed to easily navigate, this guide can be downloaded for easy reference.

Materials of Construction

Understanding materials of construction is essential to the accurate selection of valves, pipe, tubing, fittings and more. Designed to easily navigate, this guide can be downloaded for easy reference.