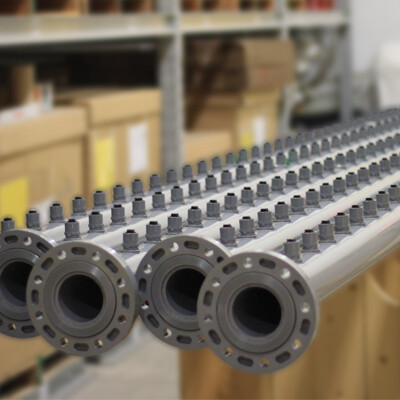

Thermoplastic Manifolds – MN Series

MN Series Thermoplastic Manifolds

The Chemline MN Series plastic manifolds provide a superior alternative to metal manifolds in many applications. State of the art CNC welding technology guarantees higher quality and reliability than socket fusion, hand welding or cementing, aiding retention of the component piping pressure rating in most cases, and all units are pressure tested to meet customer requirements. Various end connections are available to allow easy mating to any piping system, whether cemeted, threaded, flanged, grip and groove.

Chemline fabricates manifolds in a wide variety of thermoplastics, pipe sizes, configurations and end connections by CNC machine. The resulting product is stronger, more reliable, more dimensionally accurate and more cost effective than steel for production runs.

-

Size:3" to 12"

-

Ends:Plain, Threaded, Socket, Grooved or Capped

3" to 12"

Plain, Threaded, Socket, Grooved or Capped

Features & Benefits

- CNC Welding Technology

CNC saddle / butt fusion results in the capability of welding more types of branches with stronger,more reliable and more accurate welds than other technologies such as socket fusion, hand welding or cementing. - Design Validation

Validation of unique customer designs for production through destructive and impact tests, and pressure testing of sample pieces to guarantee high product quality and reliability. - Stringent Quality Control

Computer control of all welding aspects, and pressure testing, result in products capable of meeting customers quality control and reporting standards including PPAP and other schemes. Verification of finished manifold dimensions for confirmation of manufacturing accuracy. - Weld Traceability

Downloadable welding parameters are recorded for each weld and saved for customer traceability. - Repeatability

Welding parameters are saved on computer for reproduction of identical manifolds.

Technical Documents

Commonly used in these markets

Environmental

Process Industrial

High Purity Water

Aquatic Life Support

Utility Water

Valve Specification Guide

Engineering specifications are crucial as they provide precision, clarity, quality assurance and compliance in your projects. Download to save you time and assure accuracy in your specifications.

Chemical Resistance Guide

Corrosion resistance is an important factor in selecting the right material of construction for valves, pipe, tubing, fittings and more. Designed to easily navigate, this guide can be downloaded for easy reference.

Materials of Construction

Understanding materials of construction is essential to the accurate selection of valves, pipe, tubing, fittings and more. Designed to easily navigate, this guide can be downloaded for easy reference.